EXTRACTION & MANUFACTURING

Extraction

Groupe Emile presses its oilseeds and fruits at Pont Saint-Esprit, in the Gard region of France.

Each oil is obtained by a slow, gentle mechanical process, without any chemical treatment. This method preserves the flavor, nutritional and organoleptic qualities and cosmetic properties of organic oilseeds.

-

- 3,000 tonnes pressed each year

- 0 chemical treatment

- 0 refining.

First cold-pressed oil

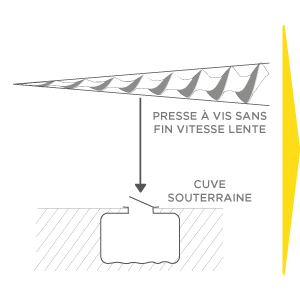

Groupe Emile uses a traditional, artisanal method of production, using carefully-maintained old screw presses for slow, gentle oil extraction.

The oil mill still has the old screw presses from the early days, acquired in the 1960s.

These old presses run very slowly, thanks to a worm screw, at temperatures below 60°C. The seeds are therefore heated less and their properties are preserved. First cold-pressed virgin oils preserve the full value of natural fatty acids and vitamins. This method enables the oils to deliver the flavor and finesse of the fruit or seed from which they are derived.

The traditional manufacturing processes that characterize Emile Noël oils combine health benefits with the pleasure of taste, health and gastronomy.

5 Manufacturing steps

Step 1

Seed reception

- Visual inspection

- Laboratory quality analysis

- Organic certificate control

- Lot acceptance and registration

- 1st sorting by separator before eb silo storage

Step 2

Seed preparation

- Mechanical shelling

- Dust removal by separator, pulling, brushing

- Dust extraction

Step 3

Seed crushing

- Low-temperature first-press oil production

- Cake recovery

Step 4

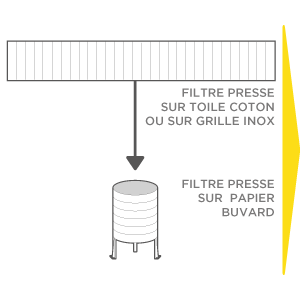

Filtration

- Impurity removal

- Wax removal

- Oil clarification

Step 5

Packaging

- Tinted glass bottle

- Batch number and best-before date recorded

Group product manufacturing

Groupe Emile manufactures its oils and feeds in the south of France at Pont-Saint-Esprit.

Traditional know-how and computerized control are combined to ensure optimum control of the manufacturing parameters: seed preparation, crushing on latest-generation screw presses, filtration and bottling on an automated line under nitrogen to protect the edible oil from oxidation.

-

- ORGANIC SEED OILS for the food and cosmetics industries

- ORGANIC TOWERS for animal feed

- ORGANIC DEHULED FLOURS for gluten-free products

Bottling

Cosmetic products

Building on its know-how as an oil maker, Groupe Emile drew on this expertise to develop its range of organic and natural cosmetics with the Emma Noël brand in 2004.

Our experts work in our specialized laboratory to analyze the quality and physico-chemical characteristics of organic virgin vegetable oils, in order to develop cosmetic products with recognized characteristics.

Oils are analyzed according to their micro-nutrient content (such as Omega 3, 6 and 9, Vitamin E…) to offer a range of products with beneficial effects for skin, body or hair.